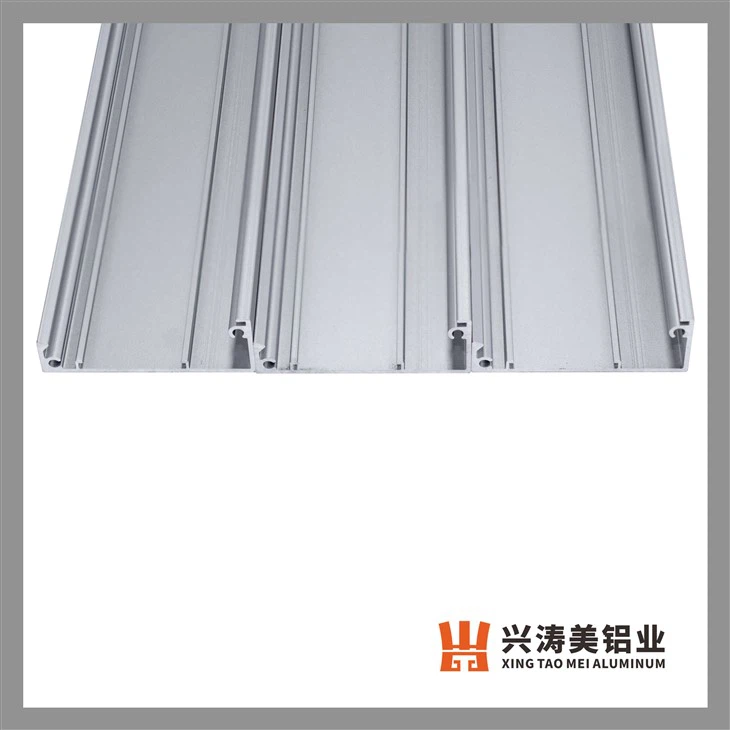

Product Description

ProTolerant LED Aluminum Extrusion Channel offers superior precision with tight tolerances, designed to perfectly house LED lights for optimal performance and aesthetics. Its durable aluminum construction ensures long-lasting use in any lighting application.

| Item Name | ProTolerant LED Aluminum Extrusion Channel | |

| Material | Aluminum Alloy 6063-T5 | |

| Dimensions | Length |

All Customized |

| Width | ||

| Height | ||

| Thickness | ||

| Colors | Silver, Gold, Black, Champagne, Bronze | Other colors available |

|

Surface Treatment |

Anodized, Sand-blasted, Powder Coated, Brushed, Polished, Mill-finished, Wood Grain |

Available in customised finishes on request |

| Services | 1. Comprehensive Services: Including mould opening, melting, extrusion, anodizing, cutting, and punching, all in one place. | |

| 2. OEM & ODM | ||

| 3. Free color samples provided | ||

| Payment |

T/T 30% deposit, Balance 70% paid before delivery |

|

| Package |

Pearl Cotton Interlayer, Poly Bag, PVC Heat Shrink Film, Carton or Wooden Pallet |

|

| Remarks | Prices vary by surface treatment and deep processing level | |

| Custom sizes, colors, surface treatments, and deep processing | ||

| Drawing design services available |

Color Options

Choose from a wide range of color options such as brushed silver, matt black, and gold, with a high-quality anodized surface treatment and additional finishes like brushed and powder coating for a unique look.

Anodizing

Anodizing is a process that makes aluminum stronger, more resistant to corrosion, and better looking by creating a protective oxide layer.

Cleaning

Aluminum is cleaned with basic or acidic solutions to remove oil, dirt, and oxidation. This helps the next layer stick properly.

Etching (Optional)

In this step, acid (like sodium hydroxide) is used to make the surface matt or textured.

Anodizing

The aluminum is placed in a sulfuric acid bath, where it becomes the anode. An electric current makes oxygen ions react with the surface to form a tough aluminum oxide layer. The thickness of the layer depends on the time and current used, providing more protection.

Package & Shipping

Our packaging process includes durable protective wrapping and sturdy cartons to ensure your order arrives in top condition, with shipping available to most countries.

About Us

Production Base

--Initially based in Dali Town, relocated to Sanshui in 2006.

--The factory covers an area of 30,000 square meters.

--Currently a comprehensive aluminum production enterprise with an annual output exceeding 20,000 tons.

Scale and Team

--Employs over 350 staff members.

--Renowned in the industry for high-quality products and a trustworthy reputation.

Equipment and Technology

--2 melting furnaces with a capacity of 25 tons each to ensure high-purity aluminum bars.

--8 extrusion lines, 1 complete anodizing line.

--Various deep-processing machines for punching, drilling, and cutting.

Exhibition Participation

--Regularly participates in major international trade shows to showcase our innovative products.

--Engages with clients and industry professionals to expand market reach.

--Demonstrates our commitment to quality, technology, and global industry trends.

Contact Us

For inquiries or to request more information about the ProTolerant LED Aluminum Extrusion Channel,

please feel free to reach out to us:

Phone: +86-757-87360023

Email: market@xtm-alu.com

Address: Sanshui District, Foshan City, Guangdong Province, China

Business Hours:Monday to Friday: 8:30 AM - 5:30 PM (GMT +8)

Our team is ready to assist you with any questions or custom design requests. We look forward to hearing from you!